Corded Hot Melt Strapping has revolutionized the baling industry by offering a highly reliable and efficient solution for securing bales of cardboard, plastic, and other compressible materials. Whether you operate a waste recycling plant or handle bulk packaging, this type of strapping ensures tighter bales and stronger knots, making it an indispensable tool for modern baling machines.

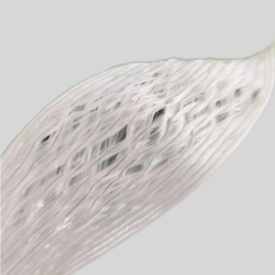

Corded Hot Melt Strapping, also known as flexible composite strapping, is manufactured using a high-strength polyester core coated with a layer of hot-melt adhesive. This unique construction provides excellent tension retention and ensures the strap stays tight, even under heavy loads. It is specifically engineered to withstand rough handling and extreme environmental conditions, offering durability and reliability unmatched by traditional steel or polypropylene strapping.

One of the primary applications of Corded Hot Melt Strapping is in waste baling machines. Here’s why it stands out:

Tighter Bales

The superior tensile strength of the strapping ensures bales are compressed to their maximum capacity. This results in a reduction in storage and transportation costs, as tightly packed bales take up less space.

Stronger Knots

The hot-melt adhesive enhances knot strength, ensuring that the bales remain securely tied during transit or storage. This reduces the risk of the bales loosening and spilling, providing an added layer of protection for goods.

Safety and Ease of Use

Unlike steel strapping, Corded Hot Melt Strapping is lightweight and safe to handle, reducing the risk of injuries during application. Its flexibility allows easy threading through baling machine mechanisms, improving overall efficiency.

While its primary use is in waste baling, Corded Hot Melt Strapping is also ideal for securing goods in industries such as logistics, agriculture, and construction. Its ability to protect products from damage while maintaining tight loads makes it an excellent choice for securing fragile items, heavy machinery, and even construction materials.

Corded Hot Melt Strapping aligns with the growing demand for sustainable packaging solutions. Its high durability means fewer replacements, reducing waste and minimizing the carbon footprint associated with packaging materials. Additionally, many manufacturers offer recyclable options, making it a greener alternative to traditional strapping methods.

For businesses aiming to enhance their packaging and waste management operations, Corded Hot Melt Strapping is a smart investment. Its combination of strength, flexibility, and ease of use ensures optimal performance, while its cost-effectiveness provides long-term savings.

In conclusion, Corded Hot Melt Strapping has set a new standard for securing bales in waste baling machines. By delivering tighter bales, stronger knots, and enhanced safety, it ensures goods are protected and operations run smoothly. Whether you are in recycling, manufacturing, or logistics, adopting this advanced strapping solution can significantly boost your efficiency and sustainability efforts.